Prefab: [adj., n. pree-fab; v. pree-fab]-adjective

1. prefabricated - to manufacture in standardized parts or sections ready for quick assembly and erection, as buildings.-noun

2. something that is prefabricated, as a building or fixture:

You would never know that such an attractive house is a prefab.

-verb (used with object)

3. to prefabricate.

Origin: 1935-1940; by shortening

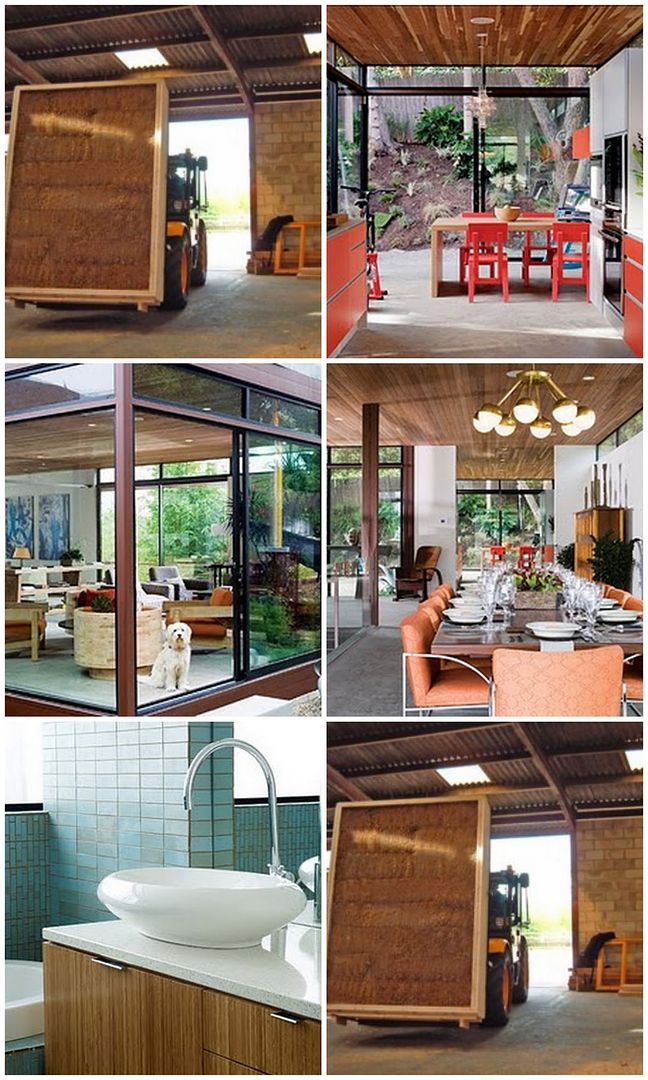

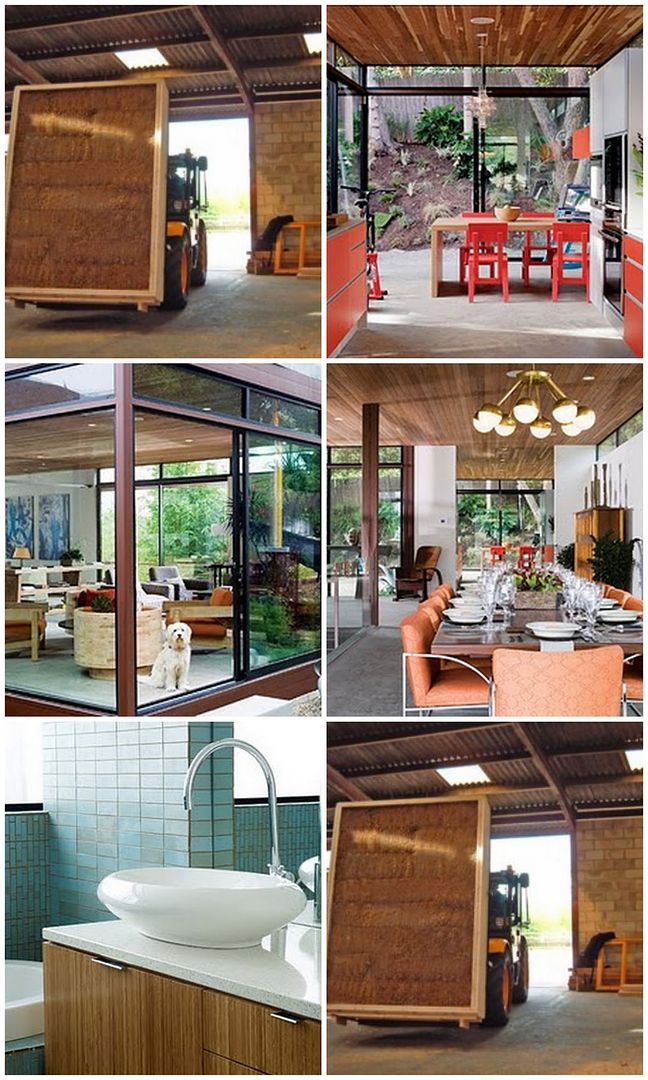

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located.Prefab has come a long way as far as design and sustainability is concerned. Ready-built or large preconstructed homes have been available in multiple forms since at least the mid-1800's. Ranging in style from cottages and mobile homes to architects' visions. Prefabricated homes stand poised to move house construction into a greener future, according to some members of the building industry. More history... There are several OUTSTANDING architects, designers, and companies out there that are working towards improving prefab and our environment at the same time. Our favorite company that excels in both design and sustainablity is LivingHomes. This company is lead by Steve Glenn, who works with leading architects to create lines of homes that feature modern form and functionality and an unprecedented level of healthy/sustainable materials and energy systems. LivingHomes worked with Ray Kappe, FAIA to design the first residence in the United States to earn LEED Platinum, which is the highest level of certification from USGBC.

LivingHomes focuses on what they call the Six Degrees of Sustainability including: energy, water, waste, emissions, carbon, and ignorance. One very intriguing 'degree' of sustainability with this company is the 'waste' impact. The company has laid out a four-step process to reduce waste. In fact, these processes allow LivingHomes to achieve about a 2% waste level — in other words, 98% of the construction products are reused, recycled or otherwise diverted from landfills. Melissa Hincha-Ownby of 1800recycling.com wrote this article on their ideals. Step one of the four-step zero waste goal is the deconstruction process. If the prospective home site has a building currently on it, LivingHomes works with The ReUse People to deconstruct the building and separate the reusable and recyclable goods. The ReUse People is a part of The ReUse Institute, and is dedicated to helping divert demolition and deconstruction materials from local landfills.

The second step is the use of locally sourced, recycled or reclaimed materials. LivingHomes made in the United States are manufactured in California, and regionally sourced materials are used when available.

Step three ensures that the process that goes into making the home can be reversed so that the product can be deconstructed and reused at the end of its life.

The final step in the process is what is called moveable millwork. In other words, you can move the walls around in your home during the design phase without the need for new building materials.

Other Fabulous PreFab Companies:

- takes an innovative approach that merges straw bale construction with prefabricated panels, with an end result that is highly attractive, energy-efficient and

very sustainable. If prefab is your thing, ModCell is definitely a company you’ll want to look into.

- This Los Angeles-based design firm run by architects Leo Marmol and Ron Radziner has a distinctly modern style using sleek lines and minimalist undertones.

- This Los Angeles-based design firm run by architects Leo Marmol and Ron Radziner has a distinctly modern style using sleek lines and minimalist undertones.

- This Los Angeles-based design firm run by architects Leo Marmol and Ron Radziner has a distinctly modern style using sleek lines and minimalist undertones.

- This Los Angeles-based design firm run by architects Leo Marmol and Ron Radziner has a distinctly modern style using sleek lines and minimalist undertones.

No comments:

Post a Comment